Else Chiller

Air Cooled Unit Chiller

Compressor Selection in Chiller Production Changes Optionally

Compressor selection in chiller production is an important factor for chiller performance and efficiency. Chiller compressors are the heart of the cooling system and start the cooling cycle by compressing the refrigerant.

The main factors to consider when choosing chiller compressors are:

- Capacity:The cooling capacity of the compressor is determined by the size of the environment that the chiller needs to cool.

- Efficiency:The efficiency of the compressor shows the amount of energy consumed according to the cooling capacity.

- Noise level:The noise level of the compressor should be taken into consideration in terms of the noise level of the place of use.

- Cost:The cost of the compressor is an important factor in chiller production.

Chiller compressors are basically divided into four categories:

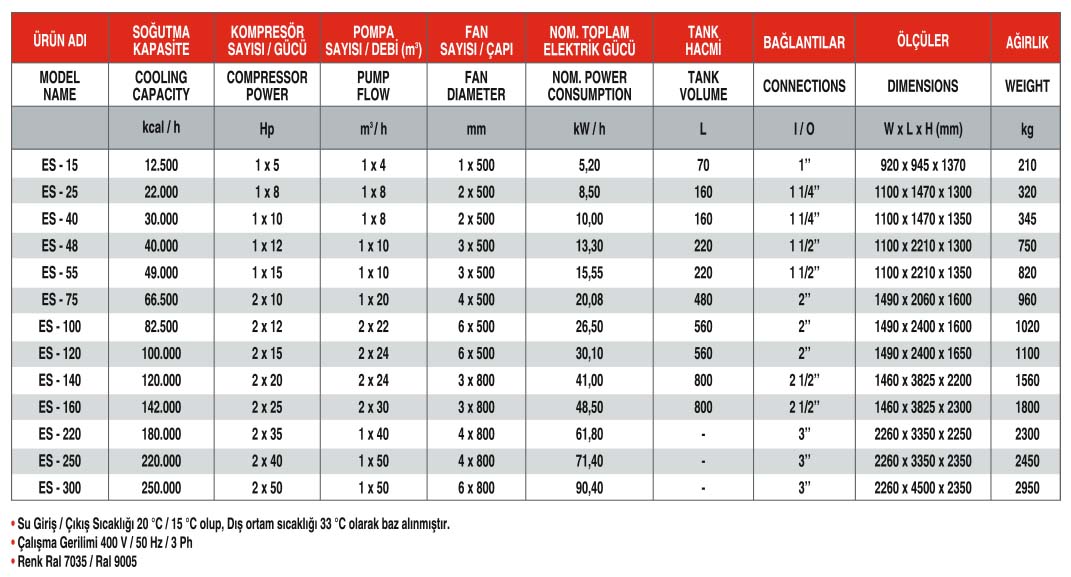

Strong Series Air Cooled 2kw-800kw Chiller

Piston compressors are the most commonly used chiller compressors. Their simple and reliable structure makes them easy to maintain and repair.

Encool Series Air Cooled 250 kW-1000 kW Chiller

Screw compressors are compressors that offer higher efficiency and performance. They are more energy efficient and produce less noise.

Quality Series Air Cooled 2kw-800kw Chiller

Due to its advantages such as high efficiency, low noise level and low maintenance requirement, it is one of the ideal compressors for chiller cooling systems.

Compressors used in chiller production are generally in one of the categories mentioned above. When selecting a compressor, factors such as the conditions of the environment where the chiller will be used, the required cooling capacity and efficiency should be taken into consideration.

Chiller compressor selection may be optionally changed in chiller production. This may vary depending on the conditions of the environment where the chiller will be used and the needs of the customer.

For example, lower cost piston compressors may be preferred in low capacity chillers. Screw compressors that offer higher efficiency and performance may be preferred in higher capacity chillers.

In addition, if the noise level of the environment where the chiller will be used is high, compressors with lower noise levels may be preferred.

Chiller compressor selection should be made by chiller manufacturers according to the needs of the customer.

Please contact our customer consultant for the system suitable for your business.

Water Pump Selection in Chiller

- Capacity: The capacity of the water pump must be compatible with the cooling capacity of the chiller. The capacity of the water pump is determined by the size of the environment that the chiller needs to cool.

- Efficiency: The efficiency of the water pump must be as high as possible. The efficiency of the water pump indicates the amount of energy used to move the cooling water.

- Noise level: The noise level of the water pump should be considered in terms of the noise level of the location of use.

- Cost: The cost of the water pump is an important factor in chiller production.

- Pump type:Water pumps used in chillers are usually centrifugal pumps or screw pumps. Centrifugal pumps are the more commonly used water pumps. Screw pumps are water pumps that offer higher efficiency and performance.

- Material:Water pumps used in chillers are usually made of stainless steel or brass. Stainless steel pumps are more corrosion resistant and have a longer life. Brass pumps are more cost-effective.

Importance of Electrical Equipment in Chillers and Optional Brand Selection

Fan Selection in Chiller

- Condenser fans: Used to cool the hot refrigerant coming out of the compressor.

- Evaporator fans: Used to remove heat from the environment to be cooled.

- Capacity: The capacity of the fans must be suitable for the cooling capacity of the chiller. The capacity of the fans is determined by the air flow rate per minute of the fan.

- Efficiency: The efficiency of the fans indicates the cooling performance of the fan. The efficiency of the fans is determined by the electricity consumption of the fan.

- Noise level: The noise level of the fans should be taken into consideration in terms of the noise level of the place of use.

- Cost: The cost of the fans is an important factor in chiller production.

The Importance of Choosing Gas Brand in Chillers

- Performance: The gas brand directly affects the performance of the chiller. More efficient gas brands allow the chiller to consume less energy and offer lower operating costs.

- Efficiency: The gas brand also affects the efficiency of the chiller. More efficient gas brands allow the chiller to provide more cooling and use less refrigerant.

- Environmental impact: The gas brand also affects the environmental impact of the chiller. Some gas brands may be more environmentally friendly than others.

- Cost: The gas brand also affects the cost of the chiller. Some gas brands may be more expensive than others.