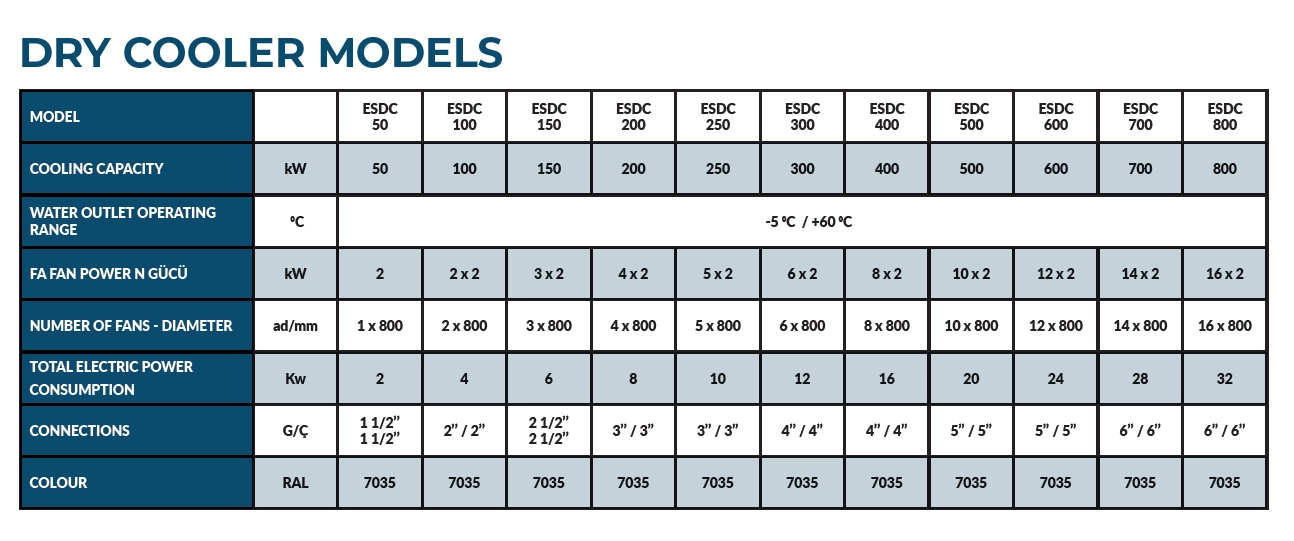

DRY COOLERS

Thanks to its energy efficiency, it reduces operating costs by an average of 60% – 70%.

Dry coolers are devices used to cool process water with ambient temperature. High-performance dry coolers are manufactured in accordance with horizontal or vertical air flow, which increases the heat transfer coefficient with copper pipes.

DRY COOLERS

- Horizontal or Vertical type design

- It is tested at 20 Bar pressure.

- Suitable for outdoor use.

- It can operate at ambient temperatures up to +60°C.

- Thanks to the closed circuit operating system, contamination and calcification are prevented.

- There is automatic air and water discharge.

- It is manufactured in accordance with the gradual operating principle depending on the need.

Advantages of Dry Coolers

- Increases energy efficiency: Compared to water-based cooling systems, it provides energy savings by providing the cooling system with the air in the environment.

- Provides an environmentally friendly solution: Uses less water compared to water-based cooling systems. Thus, it helps to protect water resources.

- Provides high performance: Provides efficient cooling of process water thanks to high-performance heat transfer.

Else Chiller Why Choose

Capacity Control

It is the process of adjusting the operating speed by activating the compressor and fans according to the cooling needs of the system. In this way, it prevents the device from working more than necessary and provides system efficiency and energy savings in businesses.

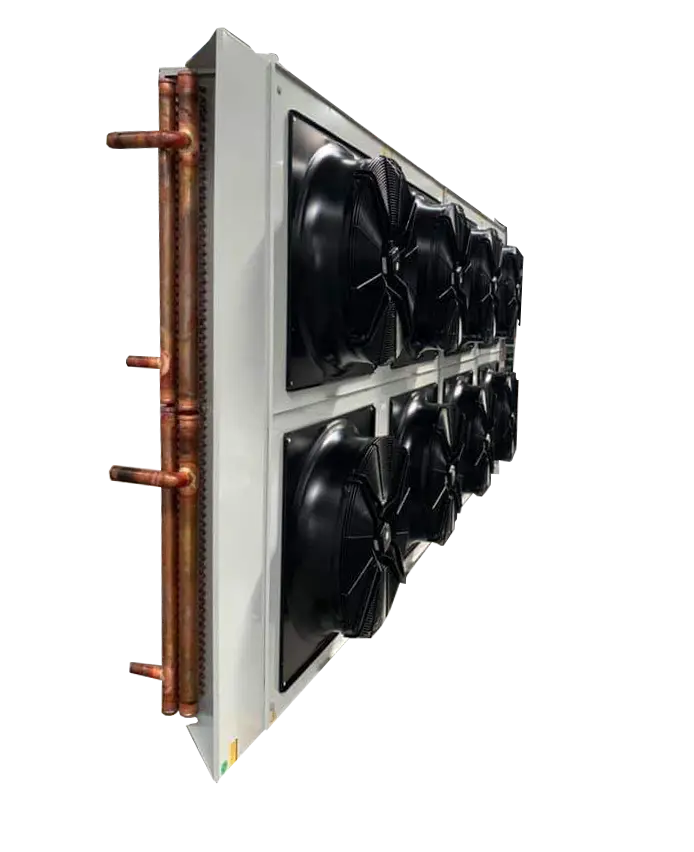

Copper Condenser for High Performance, Efficiency and Durability

• Long-lasting

• Efficient

• Energy Saving

SPOUSE AGING

In this system, the compressors are activated and deactivated in sequence according to the cooling need. This ensures that the compressors work at the same rate and have a longer life.

HEAT EXCHANGER (SHELL & TUBE)

Above the standards, copper thickness of 0.41 mm is used.

REDUCE YOUR CARBON FOOTPRINT!